Laminating and Contour Cutting with ProTec Series 3960

ProTec Series 3960 is an excellent choice for protecting your graphics, but can bring unique challenges when laminating or contour cutting due to its thickness.

Laminating Tips

ProTec Series 3960 is designed to be laminated cold. All heaters in the laminator should be turned off prior to the lamination process.

- Keep the production area clean and dust free to prevent particulates from contaminating the lamination process.

- Use a static string or static bar that is grounded to the frame of the laminator to reduce static.

- Use proper tension to ensure that Series 3960 is laminating straight.

Contour Cutting Tips

Prior to the contour cutting process, all heaters (pre, print and post) on hybrid devices such as Roland XR-640 (with cutter and printer in one) must be turned off and allowed to cool to room temperature.

- Highly recommended to use a dedicated contour cutter that can reach at least 300gF in cut force.

- For contour cutters that cannot reach 300gF, 2-3 cut passes can be performed if your cutter is capable of that function.

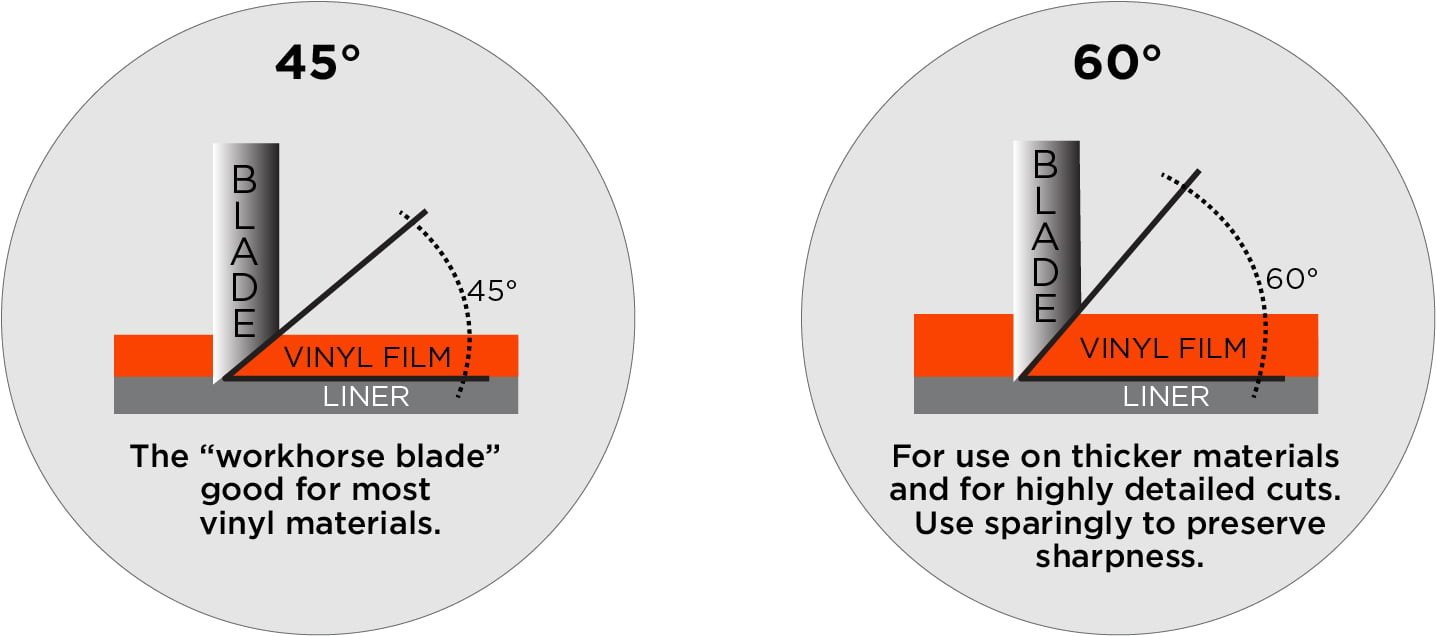

- Use a 60° (Japan 30°) tough OEM blade (super-steel or cemented carbide) that is intended for thick materials.

- Lower the speed of the cutter to protect the blade.

- Perform many test cuts to ensure proper cutting conditions are met before beginning the job.

- Avoid using sheet cut/cross cut function (these blades may not be able to cut the film). Instead always hand cut to detach the graphic using a slitter tool or sharp blade.

TIP_52_-_Laminating_and_Contour_Cutting_with_ProTec_Series_3960_-_ENG